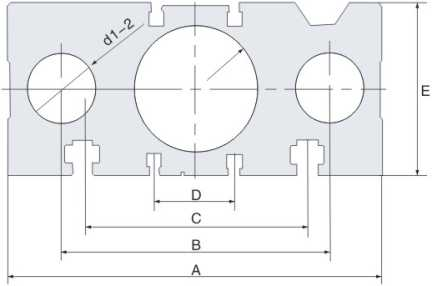

TCM-A/TCM-B Ọpa Itọsọna TCM-A

TCM-A (φ12-80) Series Silinda Tube

| No | d | d1-2 | A | B | C | D | E |

| 1 | φ12 | φ10 | 58 | 41 | 37 | 9 | 26 |

| 2 | φ16 | φ12.5 | 64 | 46 | 38 | 10.5 | 30 |

| 3 | φ20 | φ14.5 | 83 | 54 | 44 | 12.5 | 36 |

| 4 | φ25 | φ18 | 93 | 64 | 50 | 15 | 42 |

| 5 | φ32 | φ22.5 | 112 | 78 | 63 | 19.5 | 48 |

| 6 | φ40 | φ22.5 | 120 | 86 | 72 | 25 | 54 |

| 7 | φ50 | φ27.5 | 148 | 110 | 92 | 33 | 64 |

| 8 | φ63 | φ27.5 | 162 | 124 | 110 | 34 | 78 |

| g | φ80 | φ34 | 202 | 156 | 140 | 48 | 91.5 |

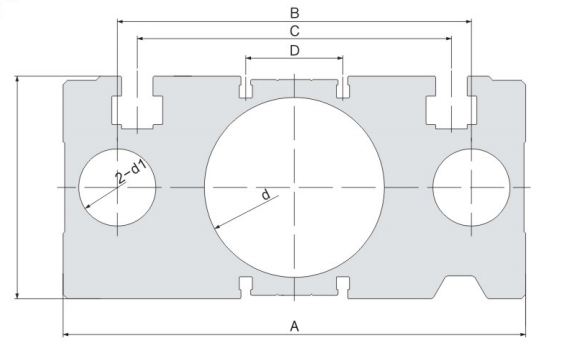

TCM-B (φ12-63) Series Silinda Tube

| NO | d | 2-d1 | A | B | C | D | E |

| 1 | φ12 | φ10 | 58 | 41 | 37 | 9 | 26 |

| 2 | φ16 | φ13 | 64 | 46 | 38 | 10.5 | 30 |

| 3 | φ20 | φ17 | 83 | 54 | 44 | 12.5 | 36 |

| 4 | φ25 | φ18 | 93 | 64 | 50 | 15 | 42 |

| 5 | φ32 | φ22.5 | 112 | 78 | 63 | 19.5 | 48 |

| 6 | φ40 | φ22.5 | 120 | 86 | 72 | 25 | 54 |

| 7 | φ50 | φ27 | 148 | 110 | 92 | 33 | 64 |

| 8 | φ63 | φ27 | 162 | 124 | 110 | 34 | 78 |

Awọn ohun elo ti Aluminiomu Alloy Profaili Aluminiomu pneumatic cylinder tube: aluminiomu alloy 6063 T5

Iwọn ipari wa jẹ 2000mm, ti o ba nilo gigun miiran, jọwọ larọwọto lati sọ fun wa.

Anodized dada: Inu tube-15 ± 5μm Ode tube-10 ± 5μm

Awọn adehun si apẹrẹ FESTO, SMC, Airtac, Chelic ati bẹbẹ lọ.

Ni ibamu si boṣewa ISO 6430 ISO6431 VDMA 24562 ISO15552 ati bẹbẹ lọ.

Lo fun boṣewa silinda, iwapọ silinda, mini silinda, Meji silinda Rod, Ifaworanhan silinda, Slide Table cylinder, Gripper ati be be lo Tun fun diẹ ninu awọn pataki gbọrọ.

Iṣọkan Kemikali:

| Kemikali Tiwqn | Mg | Si | Fe | Cu | Mn | Cr | Zn | Ti |

| 0.81 | 0.41 | 0.23 | <0.08 | <0.08 | <0.04 | <0.02 | <0.05 |

Ni pato:

| Kikanra ẹdọfu (N/mm2) | Agbara ikore (N/mm2) | Agbara (%) | Dada Lile | Ti abẹnu Iwọn Yiye | Ti abẹnu Roughness | Titọ | Aṣiṣe Sisanra |

| Sb 157 | S 0.2 108 | S8 | HV 300 | H9-H11 | <0.6 | 1/1000 | ± 1% |

Ifarada Ti Aluminiomu Alloy Tube:

| TOLERANCE OF Aluminium alloy TUBE | ||||||

| Bore Iwon | GBIGBE | |||||

| mm | H9(mm) | H10(mm) | H11(mm) | |||

| 16 | 0.043 | 0.07 | 0.11 | |||

| 20 | 0.052 | 0.084 | 0.13 | |||

| 25 | 0.052 | 0.084 | 0.13 | |||

| 32 | 0.062 | 0.1 | 0.16 | |||

| 40 | 0.062 | 0.1 | 0.16 | |||

| 50 | 0.062 | 0.1 | 0.16 | |||

| 63 | 0.074 | 0.12 | 0.19 | |||

| 70 | 0.074 | 0.12 | 0.19 | |||

| 80 | 0.074 | 0.12 | 0.19 | |||

| 100 | 0.087 | 0.14 | 0.22 | |||

| 125 | 0.1 | 0.16 | 0.25 | |||

| 160 | 0.1 | 0.16 | 0.25 | |||

| 200 | 0.115 | 0.185 | 0.29 | |||

| 250 | 0.115 | 0.185 | 0.29 | |||

| 320 | 0.14 | 0.23 | 0.36 | |||

FAQ:

Q1: Kini awoṣe TCM?

A: Ẹya ọja

1. JIS boṣewa ti wa ni imuse

2. Awọn itọnisọna meji ti irin-ara ti o ni pataki ati titọka ila tabi itọnisọna idẹ ni a lo lati ṣe idiwọ yiyi.Wọn le ru iyipo giga ati fifuye radial.

3. Ẹrọ awakọ ati ẹyọ itọnisọna wa ni agba kanna ti ko si awọn ẹya ẹrọ afikun ti a nilo pẹlu aaye ti o kere ju ti o nilo afẹfẹ afẹfẹ jẹ aṣayan ati pe o rọrun lati fi sori ẹrọ.

4. Isalẹ, ẹgbẹ ẹhin ati fifọ awo ti ara akọkọ ni atele ni awọn itọnisọna iṣalaye gangan meji (Wo PA orifice ati orifice ni aaye XX), eyi ti o le pese fifi sori ẹrọ iṣalaye pẹlu iṣedede giga fun ipo pataki.

5. Awọn aṣayan ti iṣagbesori yipada pẹlu ipese 4 iṣagbesori Iho.

6. Apẹrẹ pataki ti ara akọkọ pese ọpọlọpọ-oke;

Q2: Ti a ba ra TCM, ṣe o ṣee ṣe pẹlu anodizing fun Aluminiomu Air Cylinder Tubes?

A: Cylinder Pneumatic yii ko ṣe iṣeduro lati jẹ oxidized, nitori pe alabara nilo lati ge ara rẹ ati lẹhinna ṣe ilana rẹ lẹhinna ṣe itọju atẹgun lẹhin rira rẹ.

Q3: Kini ipari ti a ba paṣẹ Pneumatic Cylinder Tube Pipe?

A: Gigun naa jẹ mita 2.

Q4: Wfilani akoko ifijiṣẹnipa Aluminiomu Profaili Fun Air Silinda?

A: ☆Ti awọn tubes ti a ṣe adani, akoko nilo awọn ọjọ iṣẹ 50-60, ṣugbọn ti o ba jẹ fun awọn tubes boṣewa, akoko ifijiṣẹ wa jẹ awọn ọjọ iṣẹ 15-20.