TUBE CYLINDER PNEUMATIC PNEUMATIC CDQ2, BARREL PNEUMATIC PNEUMATIC

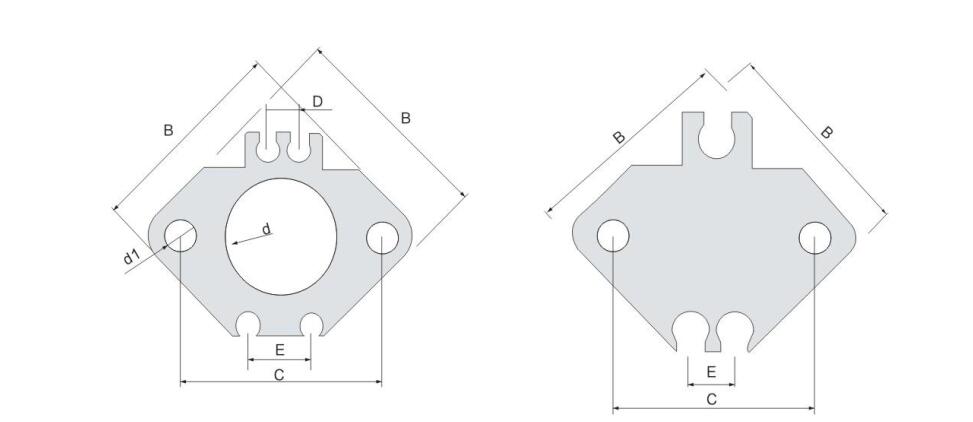

CDQ2 (φ12-25) Series Iwapọ Silinda Tube

| No | d | d1 | A | B | C | D | E |

| 1 | φ12 | 3.5 | - | 25 | 22 | - | 5.3 |

| 2 | φ16 | 3.5 | - | 29 | 28 | - | 5.3 |

| 3 | φ20 | 5.5 | - | 36 | 36 | 5.6 | 11 |

| 4 | φ25 | 5.5 | - | 40 | 40 | 5.6 | 12 |

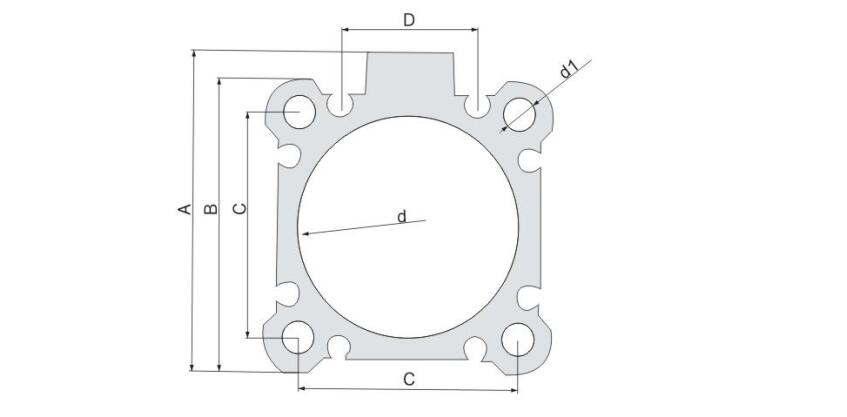

CDQ2 (φ32-100) Series Iwapọ Silinda Tube

| No | d | d1 | A | B | C | D |

| 1 | φ32 | 5.5 | 50 | 45 | 34 | 19.8 |

| 2 | φ40 | 5.5 | 57 | 52 | 40 | 24.6 |

| 3 | φ50 | 6.6 | 71 | 64 | 50 | 29 |

| 4 | φ63 | 9 | 84 | 77 | 60 | 38 |

| 5 | φ80 | 11 | 104 | 98 | 77 | 48 |

| 6 | φ100 | 11.5 | 123.4 | 117 | 94 | 63 |

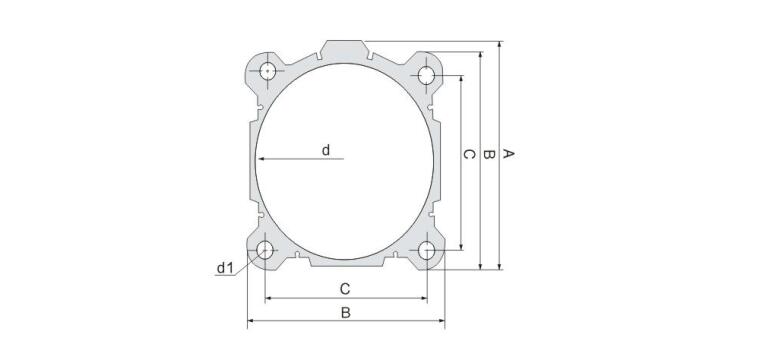

CQ2(φ125-200) Series Tobi opin Iwapọ Silinda Tube

| NO | d | d1 | A | B | C |

| 1 | φ125 | 13 | 153 | 142 | 114 |

| 2 | φ140 | 12 | 168 | 158 | 128 |

| 3 | φ160 | 14 | 188 | 178 | 144 |

| 4 | 180 | 19.5 | 203.5 | 196.6 | 161.6 |

| 5 | φ200 | 19.5 | 225.5 | 217.6 | 181.6 |

Awọn ohun elo ti Aluminiomu Alloy Profaili Aluminiomu pneumatic cylinder tube: aluminiomu alloy 6063 T5

Iwọn ipari wa jẹ 2000mm, ti o ba nilo gigun miiran, jọwọ larọwọto lati sọ fun wa.

Anodized dada: Inu tube-15 ± 5μm Ode tube-10 ± 5μm

Awọn adehun si apẹrẹ FESTO, SMC, Airtac, Chelic ati bẹbẹ lọ.

Ni ibamu si boṣewa ISO 6430 ISO6431 VDMA 24562 ISO15552 ati bẹbẹ lọ.

Lo fun boṣewa silinda, iwapọ silinda, mini silinda, Meji silinda Rod, Ifaworanhan silinda, Slide Table cylinder, Gripper ati be be lo Tun fun diẹ ninu awọn pataki gbọrọ.

Iṣọkan Kemikali:

| Kemikali Tiwqn | Mg | Si | Fe | Cu | Mn | Cr | Zn | Ti |

| 0.81 | 0.41 | 0.23 | <0.08 | <0.08 | <0.04 | <0.02 | <0.05 |

Ni pato:

| Kikanra ẹdọfu (N/mm2) | Agbara ikore (N/mm2) | Agbara (%) | Dada Lile | Ti abẹnu Iwọn Yiye | Ti abẹnu Roughness | Titọ | Aṣiṣe Sisanra |

| Sb 157 | S 0.2 108 | S8 | HV 300 | H9-H11 | <0.6 | 1/1000 | ± 1% |

Ifarada Ti Aluminiomu Alloy Tube:

| TOLERANCE OF Aluminium alloy TUBE | ||||||

| Bore Iwon | GBIGBE | |||||

| mm | H9(mm) | H10(mm) | H11(mm) | |||

| 16 | 0.043 | 0.07 | 0.11 | |||

| 20 | 0.052 | 0.084 | 0.13 | |||

| 25 | 0.052 | 0.084 | 0.13 | |||

| 32 | 0.062 | 0.1 | 0.16 | |||

| 40 | 0.062 | 0.1 | 0.16 | |||

| 50 | 0.062 | 0.1 | 0.16 | |||

| 63 | 0.074 | 0.12 | 0.19 | |||

| 70 | 0.074 | 0.12 | 0.19 | |||

| 80 | 0.074 | 0.12 | 0.19 | |||

| 100 | 0.087 | 0.14 | 0.22 | |||

| 125 | 0.1 | 0.16 | 0.25 | |||

| 160 | 0.1 | 0.16 | 0.25 | |||

| 200 | 0.115 | 0.185 | 0.29 | |||

| 250 | 0.115 | 0.185 | 0.29 | |||

| 320 | 0.14 | 0.23 | 0.36 | |||

FAQ

Q1: Kini awoṣe CDQ2?

A: CDQ2 jẹ awoṣe boṣewa SMC.O ni igbese meji, extrusion igbese kan.Ati pẹlu oofa.

Q2: Kini silinda pneumatic iwapọ?

A: Silinda Pneumatic iwapọ jẹ apakan irin iyipo ti o ṣe itọsọna piston lati ṣe atunṣe ni laini taara.Awọn ẹya silinda pneumatic iwapọ pẹlu: pneumatic cylinder aluminum extrusion tube, ideri ipari, piston, ọpa piston ati awọn ohun elo edidi.

Q3: Kini anfani fun silinda pneumatic iwapọ?

A: Silinda pneumatic iwapọ ni awọn anfani ti ọna kika, iwuwo ina, ati iṣẹ aaye kekere.

Silinda pneumatic iwapọ wa ni aaye ti o kere si, o ni eto ina, irisi ẹlẹwa, ati pe o le koju awọn ẹru ita nla.O le fi sori ẹrọ taara lori ọpọlọpọ awọn imuduro ati ohun elo pataki laisi awọn ẹya ẹrọ fifi sori ẹrọ.

Iṣẹ ti silinda pneumatic iwapọ: Agbara titẹ ti afẹfẹ fisinuirindigbindigbin ti yipada si agbara ẹrọ, ati ẹrọ awakọ n ṣe atunṣe laini, yiyi ati awọn iṣipopada.

Q4: Ṣe ipese wa pẹlu anodizing?

A: Bẹẹni, CDQ2 Series tube a le pese pẹlu anodizing.A ti wa ni iṣowo agbaye fun ọdun 17.A le pese gbogbo laini iṣelọpọ fun Factory: Lati extrusion lati pari tube Cylinder Pneumatic.

Q5: Kini iho ti tube silinda CDQ2 ti o ni?

A: 12, 16, 20, 25, 32, 40, 50, 63, 80, 100mm a ni.

Q6: Ṣe o wa lati pese awọn ayẹwo tube aluminiomu extruded?

A: Bẹẹni, Autoair ni anfani lati pese tube aluminiomu extruded fun ọ lati ṣayẹwo didara, Ni deede, apẹẹrẹ jẹ ọfẹ fun fifipamọ iye owo rẹ, Ṣugbọn yoo nilo iye owo ọpa ti o ba jẹ iwọn tube aṣa.